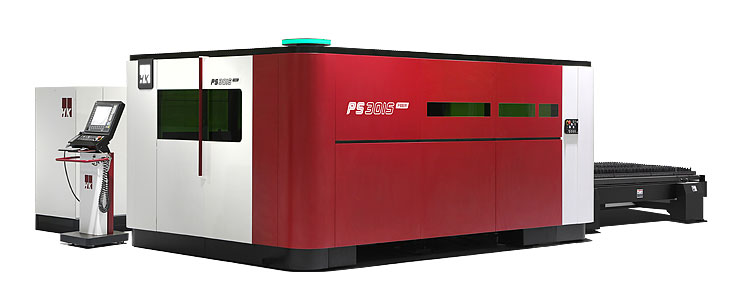

Laser Cutting Systems

Are you interested in building your own laser cutter kit plans using CO2 laser tube or fiber laser generators? This allows you to create 2D/3D profiles and shapes on metals, wood, plywood.

Based on table size, laser cutting machines can be classified into handheld, portable or small, mini, benchtop, desktop and tabletop laser cutter systems. Make sure you measure your workshop space before buying.